WE’RE LEADING A PROTOTYPING

PROJECT TO TRANSFORM

CANADIAN WOOL...

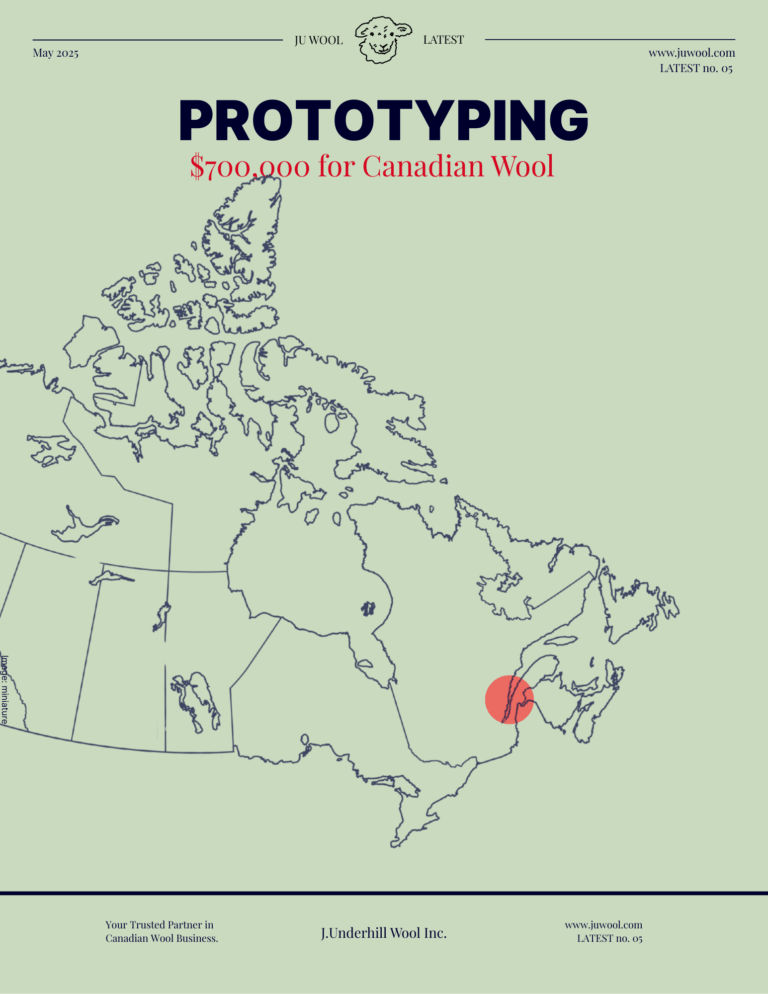

Welcome to this edition of my LATEST, where I finally get to announce some exciting news that I’ve been holding onto. JU WOOL, along with several ecosystem partners, has been awarded a historic subsidy to prototype with Canadian wool and develop a blueprint for an innovative regional supply chain. The Quebec Minister of Economy, Innovation, and Energy has granted us a matching subsidy valued at $700,000 for a phase 1 project. This opens up incredible opportunities, not just for my company and our project partners, but for the future of our Quebec ecosystem and the entire Canadian wool value chain. Read on to discover more about our partners, the funder, the initiative, and what we hope to achieve from this unprecedented opportunity.

THE PROJECT MODEL

HOW IT STARTED

The project began in December 2023, following the IWTO Montreal Round Table. Serge Lemieux, President of Lemieux Spinning, suggested we seek out a collaborative subsidy to prototype using Canadian wool. We enlisted Dany Charest, Executive Director of TechniTextile, to help us identify funding streams. Dany proposed a little known provincial subsidy that aligned with our vision of prototyping Canadian wool while thoroughly analysing the potential of our ecosystem.

I volunteered to draft the project model. My rather comprehensive pitch included a detailed profile of the sheep industry, highlighting the unique characteristics and challenges of Canadian wool. Alongside that, I put together a robust financial model to demonstrate the project’s viability. In hindsight, I may have gone a little overboard with the sheep industry stuff. A dozen-or-so pages on breeds and farm management systems was likely overkill. A poor soul in a government office now knows more about abattoirs that they ever expected.

Our proposal was submitted on October 30, 2024, and included 6 companies, 5 supporters, 3 consultants and 2 contractors. We outlined an ambitious plan for prototyping semi-finished and finished wool products, leveraging the collective expertise of our ecosystem partners. We emphasized the importance of creating a closed-loop manufacturing chain within Quebec, where all processes occur in close geographic proximity to reduce environmental impact, lower costs, and improve efficiency.

On March 30, 2025, we received the exciting news that our proposal had been approved. This historic subsidy, valued at $700,000, marks a significant milestone for my work in the industry and opens up unprecedented opportunities for innovation, collaboration, and growth, not only for JU WOOL but for the entire Canadian wool value chain.

THE FUNDER AND THE PROMOTER

Our project is funded by the Québec Ministère de l’Économie, de l’Innovation et de l’Énergie under PAPDE Volet 2 subsidy – described as “Support for the Development of Strategic Sectors and Regions”. Who knew there was a program designed (almost) specifically for a regional wool ecosystem? Serendipity is wonderful thing.

The subsidy requires a promoter for liaison purposes with the Minister and administrative support to the partners. We couldn’t have asked for a more dynamic and talented promoter in TechniTextile. Founded in 2017, TechniTextile leads innovation, business development and advocacy for the entire Quebec textile industry. Their experience and guidance ensured our success.

PARTNER ENTREPRISES

Our project unites six Quebec textile enterprises, each specializing in different aspects of the wool supply chain. We intend to leverage the unique strengths of each company to create a powerful synergy. Here are the partners:

JU WOOL is the largest partner in the project in terms of investment. I’m the project manager and I will be handling wool acquisition, wool testing, ecosystem analysis, data compilation and reporting.

Lemieux Spinning will test different types of yarns, blends and process improvement. They will use the opportunity to evaluate equipment enhancements in a subsequent phase.

Milo and Dexter will test knitting and circularity using Canadian wool and wool blends. They will collaborate closely with Lemieux on price and quality advantages.

Moulin Laine Pierre will refine operations and test wool on new machinery for cloth and rug manufacturing.

Duray Canada will test wool spinning and knitting on new sock and mitten products. Duray is well into prototyping. JU WOOL collaborated on a prototype Canadian wool sock and mitten project in 2023/2024 – which performed well in Christmas 2024 wholesale sales.

Groupe CTT is a textile laboratory in St-Hyacinthe, Quebec. They’ve recently acquired OFDA greasy wool testing equipment and will supply testing service of greasy wool, clean yarn and cloth.

SUPPORTER ORGANIZATIONS

We are grateful to the industry organizations who provided letters of support and encouragement for the project: Les Éleveurs ovins du Québec (LEOQ), La Société des éleveurs de moutons de race pure du Québec (SEMPRQ), Centre d’expertise en production ovine du Québec (CEPOQ), the Canadian Wool Council (CWC) and the International Wool Textile Organization (IWTO).

WE’RE LEADING A PROTOTYPING

PROJECT TO TRANSFORM

CANADIAN WOOL...

Within an 18-month timeframe the plan is to move 6,000 lb of commercial crossbred wool into processing for semi-finished and finished wool goods. We’ll cover a diverse range of materials, processes, interventions, products, and tests; each designed to evaluate the tolerances, versatility and outcomes of Canadian wool. While we already know that we can work with Canadian wool, this opportunity provides the necessary support to study the fibre more closely. We’ll see how it behaves and what we can do to adapt to it – and help it adapt to us. This will also be an opportunity to see how well the ecosystem fits and works together.

Beyond the overarching objectives, each partner has developed their unique lines of inquiry, exploring material, equipment, procedures, and market opportunities. A strict code of confidentiality is maintained among the partners. Each partner retains the liberty to share as much or as little of their experience as they wish.

For JU WOOL’s inquiry, I’m addressing four strategy areas in addition to project management, support and reporting.

I will share my research and findings in my LATEST blogs so please be sure to check back each month.

REGIONAL INTEGRATED

MANUFACTURING:

AN ECOSYSTEM MODEL FOR QUÉBEC

WHAT IS CLOSED LOOP MANUFACTURING

In the wool industry, closed-loop manufacturing involves independent companies working collaboratively within a geographic zone. Proven in countries like India, the UK, and Germany, this approach fosters collaboration, knowledge sharing, and opportunity while reducing environmental impact, lowering costs, and improving efficiency. Each stakeholder remains an autonomous entity, while playing a unique role in forming a cohesive ecosystem where every transformation step occurs within the defined geographic loop.

WHY IS IT IMPORTANT FOR CANADA

For Canadian wool to compete against synthetics and foreign adversaries, we need a commercial capacity, regional manufacturing chain that bolsters our readiness to answer demand and meets or surpasses global wool management and traceability expectations.

The ecosystem must consider faster response times to opportunities, cost-efficient production, reduced transportation and therefore lower environmental impact while addressing growing concerns about traceability, waste management and product end-of-life.

Currently, we face challenges such as costly transportation, wool variability due to diverse breeds, and environmental impacts from manufacturing inefficiencies. But I feel there is a solution imbedded in an ecosystem model whereby opportunities and risks are shouldered collectively within a reasonable proximity.

Once wool enters the ecosystem, we can leverage economies of scale to the benefit of the client, control traceability, transport, timelines and emissions. By pooling our collective expertise, we master the wool from our national clip.

WHAT’S NEXT?

TechniTextile has graciously provided us with a press agent who is managing the media release of the project. The release will be shared across Canada and through a global press network. We were advised to wait until after the federal election to make the announcement. With that behind us, I expect communications to circulate in the next week or so. You may be reading this LATEST at the same time as you’re reading the official release on line.

In the meantime, I’ve started some aspects of wool testing and I’ve put out a call for coloured wools to test blending natural colours instead of using dyes. Lots of coloured wools in BC. (Shout out to the Vancouver Island farmers who’ve reached out.)

On Friday I travel to France for the IWTO Congress in Lille. For the first time at IWTO I’ll be mentoring in Young Professionals program. Following the conference, I’ll be touring mills and visiting friends in the Alps. In parallel, my new website is launching (Merci Sarah – Tu es formidable !) and work will be wrapping up with my intern Nicolle who is helping us implement a wool inventory tracking system to replace the static system.